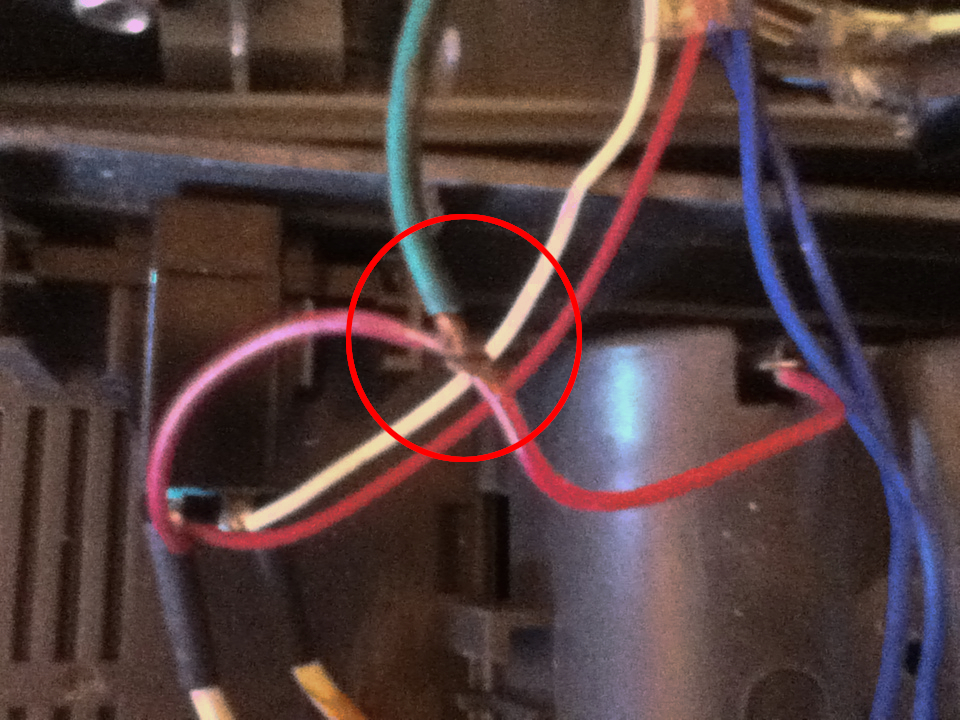

I recently came across this cassette recorder with wires sticking out the side. I thought it was probably broken, but brought it home to look at. I opened it up and found a hack job with the wiring. Wires had been spliced into the original and covered loosely with tape.

After fixing the mess of wires, I tested it out by battery. It worked but the audio cut in and out when at full volume. I found out that one of the wires was getting pinched and after fixing that it plays great. I would like to get a 6V DC power supply instead of burning C batteries, but I have really enjoyed getting this vintage cassette recorder working.